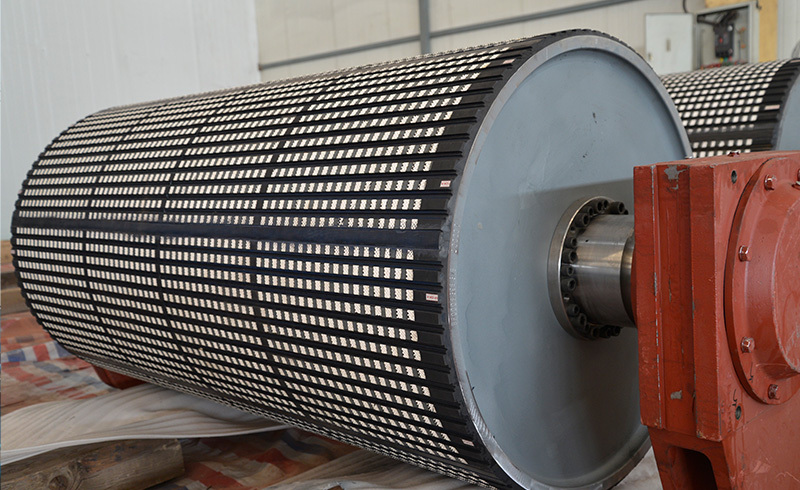

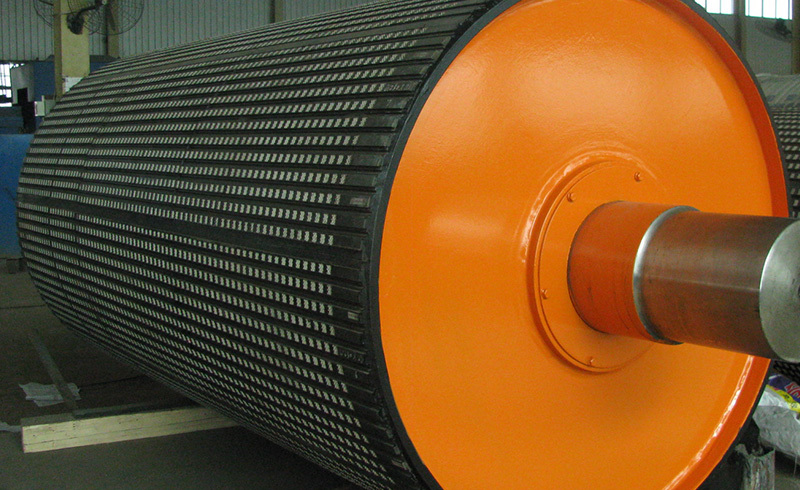

Abrasion-resistant Ceramic Lagging Pulleycoating

Anti-slip

Deflection prevention

Protecting the belt

No material accumulation on the surface

Long life

Easy to cope with harsh working conditions

- Information

Anti-slip

The ceramic surface has uniform spherical bumps, the coefficient of friction is 3 times that of traditional rubber covering, and thousands of bumps can produce positive traction when the back of the conveyor belt passes through, preventing the conveyor belt from slipping and running out of alignment, and improving the conveying efficiency;

Deflection prevention

The main reason for the deflection of traditional belt is the wear and tear of the rubber cover as well as the accumulation of material. Occasionally, the incoming material will be discharged through the grooves, and there will be no problem of material accumulation;

Protecting the belt

1、Bumps without angular design, there will be no other ceramic overlay products common raised particles of the sharp edges of the belt to bring wear and tear of the problem;

2、No relative sliding between the roller and the belt, which further protects the belt from abrasion;

3、It can reduce the tension of the belt under the same load and prolong the life of the belt;

No material accumulation on the surface

Each ceramic rubber plate has grooves spaced a certain distance apart, which enables the foreign matter (dust, soil) on the pulley to be discharged along the grooves, so that the pulley has a unique self-cleaning function, which is especially suitable for humid working environments;

Long life

The life expectancy is more than 5 times that of ordinary rubber rollers;

Easy to cope with harsh working conditions

SHC-CR shows more performance under harsh conditions such as wet, muddy, and long-distance conveying;

Impact resistance

The elasticity of the underlying rubber can play a good role in impact resistance;

Quick and easy installation

There is no need to unload the roller from the conveyor, which reduces the cost of unloading and transporting the roller, saves time, and eliminates the labour intensity and safety hazards of workers. It also eliminates the wear and tear on other parts of the belt conveyor when removing and installing the pulleys.

Get the latest price? We'll respond as soon as possible(within 12 hours)